Purchasing Manager (interim)

Client:

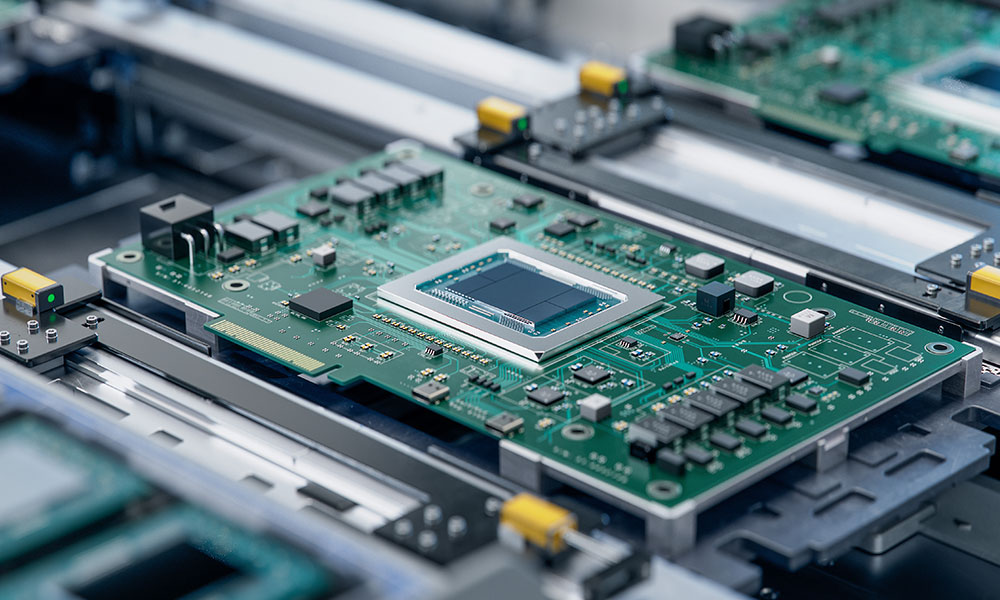

- Internationally positioned electronics service provider

Key figures of the company:

Industry: Service Provider Electronic Manufacturing Services

Turnover: approx. 19 million euros

Employees: approx. 110

Project duration: 2022 – 2023

Situation:

The client is an international electronics service provider with a wide range of products in PCB assembly as well as in device and system construction, control cabinet construction and cable assembly. The complete range of services for the development and production of electronic assemblies up to box build is also part of the range of services.

The medium-sized company supplies its customers internationally, mainly in the aviation, medical technology and industrial applications.

Due to a high number of open order backlogs, an equally large number of missing scheduling implementations of MRP proposals, internal production backlogs and a lack of efficiency in purchasing processes in day-to-day business, the prompt loss of customer reputation threatened with possible effects on order intake for 2023.

Main

Development, management and optimisation of the strategic and operational development and

process organization as well as increasing and stabilizing the material availability under

Consideration of inventory costs to ensure customer delivery dates.

Measures

- Introduction of overviews (Excel spreadsheets) of the order status of various customers incl. Definition of immediate measures to ensure material availability in 2023

- Introduction of weekly meetings with EC staff (one-on-one meetings) with a focus on material procurement, escalation management

- Introduction of a weekly EC round for general topics from day-to-day business

- Introduction of weekly meeting with sales and production interfaces for production planning and control

- Introduction of missing parts management via TEAMS folder for production

- Introduction of EK – standard worksheet for weak point and capacity analysis as well as the implementation of two workshops on the topic of time management and mood barometer with EK staff

- Introduction of communication and escalation rules against the interfaces

- Active order management in the supplier market with the aim of improving cash flow and inventories

- Conducting end-of-year discussions with the employees of the purchasing department

- Conducting job interviews

Results

- Increase in supplier reliability from 77% to 88% within 6 months in a supplier market that continues to be volatile

- Improvement of external delivery reliability to the customer from 83% to 89% within 6 months

- Reduction of the scheduled sales backlog by EUR 3.0 million within 3 months

- Turning around a negative cash flow within 4 months

On the basis of all the measures introduced and the willingness of the EK employees to support these measures, and the good communication culture within purchasing, it has been possible to secure the availability of materials for 2023 in a more stable manner, with the exception of a very small number of individual customer orders.

Special Challenges

- The high level of uncertainty and low culture of trust at the beginning of the mandate among the purchasing employees to transform into an open communication culture

- Due to the high culture of mistrust towards procurement, establishing the purchasing organization within the company as an important component and partner of a supply chain

- Recognize the rules and characteristics of a distributor’s market and successfully manage them in the interests of the company